Wheel Bearing Grease

Wheel Bearing Grease Specification

- Smell

- Mild Odor

- Ash %

- <2%

- Density

- 0.92 Gram per cubic centimeter(g/cm3)

- Color

- Dark Brown

- Grease

- Smooth, Homogeneous, Non-Fibrous

- Oil Type

- Mineral Base Oil

- Application

- Wheel Bearings, Chassis Lubrication, General Greasing

- Chemical Composition

- Lithium Soap, Mineral Oil

- Type

- Grease

- Use

- For lubrication and protection of wheel bearings

- Water Content Vol%

- <0.1%

- Weight

- 1 kg (net weight, may vary per pack)

- Packaging Type

- Tin, Bucket, Drum

- Viscosity

- Grade 2 (NLGI No. 2)

- Operating Temperature

- -20C to +120C

- Size

- 1 kg, 5 kg, 10 kg, 18 kg

- Vehicle Type

- Automotive, Heavy-Duty Trucks, Tractors, Trailers

- Pack Type

- Bucket, Drum, Pouch, Tin

- Water Washout Test

- Passes IS: 7623

- Appearance

- Smooth and glossy

- Compatibility

- Compatible with most conventional greases

- Soap Base

- Lithium

- Adhesion

- High adherence to metal surfaces

- Worked Penetration (60 Strokes)

- 265-295

- Service Life

- Extended service intervals

- Shelf Life

- 2 Years

- Drop Point

- Above 175°C

- Corrosion Resistance

- Excellent water resistance and mechanical stability

Wheel Bearing Grease Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Wheel Bearing Grease

Superior Protection for Wheel Bearings

Formulated with high-quality lithium soap and mineral oil, this grease delivers outstanding performance in wheel bearing and chassis lubrication. Its advanced water resistance and high adherence minimise wear and ensure smooth operation, even in moisture-prone environments. This makes it a top choice for demanding automotive and heavy-duty vehicle maintenance.

Extended Service Life and Stability

Engineered for extended service intervals, this grease maintains its protective properties over long periods and under mechanical stress. The excellent worked penetration and high drop point mean it stays effective even at elevated temperatures, reducing maintenance frequency and downtime.

Versatile Packaging and Applications

Available in 1, 5, 10, and 18 kg options and multiple pack typesbucket, drum, pouch, and tinthis wheel bearing grease caters to diverse needs. Its compatibility with most conventional greases and consistent performance make it a preferred choice for distributors, suppliers, and end users across various vehicle types and machinery in India.

FAQs of Wheel Bearing Grease:

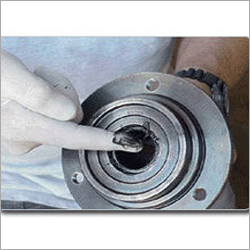

Q: How should Wheel Bearing Grease be applied for optimal performance?

A: For best results, the grease should be evenly applied to clean, dry metal surfaces, ensuring full coverage of wheel bearings or chassis parts. Excess old grease should be removed before reapplication to maintain lubrication efficiency and prevent contamination.Q: What are the main benefits of using this lithium-based Wheel Bearing Grease?

A: This grease provides excellent water resistance, high mechanical stability, and superior adherence to metal surfaces, extending service intervals and protecting against corrosion and wear. Its smooth, homogeneous texture ensures consistent coverage and reliable protection in both automotive and heavy-duty applications.Q: When is it necessary to re-grease wheel bearings using this product?

A: Thanks to its extended service life and stability, re-greasing is typically less frequent. However, it is recommended to follow the vehicle or equipment manufacturers suggested maintenance schedule, and reapply after long periods of heavy use or exposure to harsh conditions.Q: Where can this Wheel Bearing Grease be used?

A: This grease is suitable for automotive, trucks, tractors, trailers, and general machinery. It is ideal for wheel bearings, chassis lubrication, and any application requiring long-lasting, water-resistant lubrication, particularly in environments with fluctuating temperatures and exposure to moisture.Q: What packaging sizes and formats are available for this Wheel Bearing Grease?

A: The product is available in 1 kg, 5 kg, 10 kg, and 18 kg packs, offered in buckets, drums, pouches, and tins. This versatility allows distributors and users in India to select the best option for their operational needs.Q: Is this grease compatible with other types of conventional greases?

A: Yes, this grease is fully compatible with most conventional greases. However, it is always advisable to verify compatibility before mixing with other formulations to maintain optimal performance.Q: What tests and standards does this grease meet for reliability?

A: It passes the IS: 7623 water washout test and delivers a drop point above 175C, with worked penetration of 265295, ensuring consistent performance under demanding conditions and excellent resistance to water washout.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Grease Category

Multi Service AP3 Grease

Minimum Order Quantity : 1 Piece

Packaging Type : Tub, Bucket, Drum

Use : Chassis lubrication, Wheel bearings, Generalpurpose greasing

Pack Type : Tub, Bucket, Drum

Vehicle Type : Other, Automotive, Industrial, Tractor, Heavy Commercial Vehicles

Rider Grease

Minimum Order Quantity : 1 Piece

Packaging Type : Bucket, Jar, Tin

Use : Reduce Friction & Wear in Bearings and Joints

Pack Type : Tin/Plastic Container

Vehicle Type : Other, Automotive

Riders Multi Service AP3 Grease

Minimum Order Quantity : 1 Piece

Packaging Type : Plastic Jar/Bucket/Barrel

Use : Reduces friction, protects against rust and corrosion

Pack Type : Plastic Jar, Bucket, Barrel

Vehicle Type : Other, All types of automotive and industrial vehicles

Long Life Grease (APLR)

Minimum Order Quantity : 100 Kilograms

Packaging Type : Bucket

Use : Industrial

Pack Type : Bucket & Bottle

Vehicle Type : Scooter, Motorcycle, Auto, Cars, Heavy Vehicle

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS